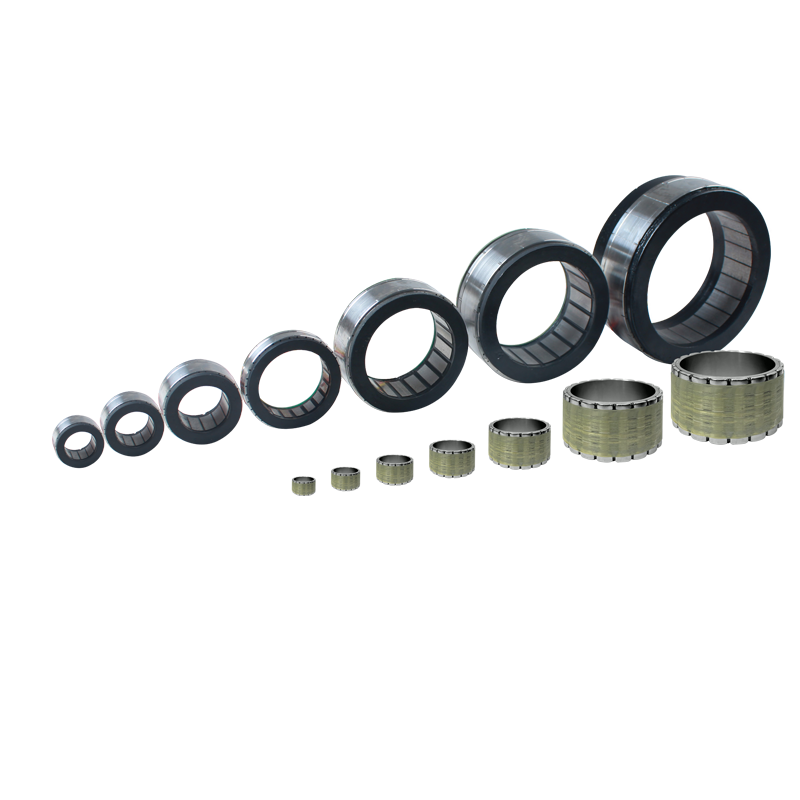

At Leadshine, we understand that precision and efficiency are at the core of modern industrial automation. Servo motors and drives form the backbone of many automated systems, providing accurate motion control for tasks ranging from assembly lines to CNC machines. These systems work together to convert electrical signals into precise mechanical movement, ensuring smooth operation and consistent performance in demanding industrial environments.

Why Integration Matters

Traditional setups often involve pairing separate servo motors with external drives, which can introduce complexity in wiring, programming, and system maintenance. An integrated servo motor simplifies this process by combining the motor and drive into a single unit. This integration reduces installation time, minimizes space requirements, and lowers the potential for errors caused by mismatched components. By streamlining these elements, your production line can operate more efficiently and with less downtime.

Performance and Reliability Benefits

Integrated solutions from Leadshine offer improved performance through optimized communication between motor and drive. This close integration ensures faster response times, higher torque accuracy, and smoother motion profiles. The compact design also helps with heat dissipation, which contributes to longer service life and greater system reliability. For businesses that demand consistent quality and minimal maintenance interruptions, this level of reliability is crucial.

Simplifying System Design

With an integrated servo motor, engineers and system designers can simplify overall system architecture. Fewer components mean fewer points of failure and easier troubleshooting. The reduced wiring and compact footprint also allow for more flexible machine designs, making it easier to upgrade or expand production lines. This simplicity does not compromise functionality; rather, it enhances overall efficiency by allowing teams to focus on operational improvements instead of complex installation procedures.

Applications Across Industries

Leadshine's integrated servo motors and drives are used across a wide range of industries, including manufacturing, robotics, packaging, and CNC machinery. They are ideal for applications requiring precise positioning, repeatable motion, and high-speed response. By implementing integrated solutions, businesses can achieve better process control, reduce energy consumption, and improve overall throughput.

Conclusion

Choosing the right motion control components is essential for achieving efficient and reliable automation. Servo motors and drives, particularly integrated solutions, offer a combination of performance, simplicity, and durability that supports modern industrial demands. At Leadshine, we provide tailored motion control products with over 27 years of experience, ensuring that your automation systems are optimized for precision and productivity. By integrating motors and drives, you gain a streamlined solution that supports consistent performance and long-term reliability across diverse industrial applications.